High-Volume Low-Speed (HVLS) ceiling fans are normally used for factories and warehouses. Among them, the most common building structure is steel structure. Therefore, many companies are quite familiar with installing ways for it. Apart from the steel structure, there are still many other building structures, such as spherical grid structures, derivation structures, and concrete structures. Let us briefly introduce the installation of concrete structures in this article.

Compared with the steel structure workshop, the relative temperature of the concrete workshop will be slightly lower in summer. This is because of the inherent property of concrete-better thermal insulation. However, the concrete workshop is usually relatively short, resulting in poor ventilation, and it will be very stuffy after a long time, which seriously affects work efficiency.

Large industrial HVLS fans can also be installed in a concrete workshop environment, and the effect is relatively good. The specific installation method is two splints, which are locked by expansion screws, tightly turn the house's beams, and then install the bracket, extension rod, host, etc. Then use expansion screws to fix the wire rope, and adjust the level of the fan to ensure stable operation without shaking and, at the same time, play a better role in safety protection.

There are several common installation methods for concrete structures.

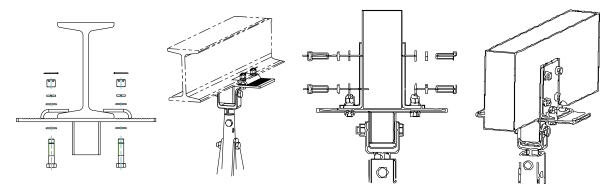

1) Formal installation for concrete structure.

Firstly, locate the holes of the L-shaped plates on both sides and fix them with expansion bolts. At least three bolts shall be punched on each side of L-shaped plates to guarantee the safety of HVLS fans. After punching holes, the L-shaped plates on both sides should be fixed parallel. At the same time, place the upper connection plate in the center of the concrete and fix the four bolts.

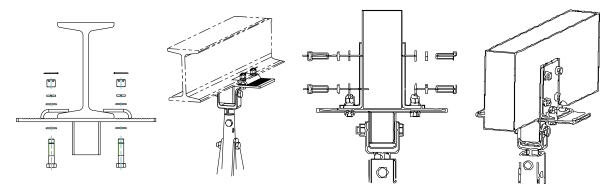

2) Reverse installation of concrete structure

First, find the hole position of the special upper connecting frames. Second, when punching holes, keep at least four expansion bolts. Third, lock four base bolts of the connecting frame when punching, and keep them in the middle level.

3) Side amount for concrete structure

First, put the special upper connecting plate into the concrete beam horizontally. After finding the hole position, turn the u-shaped hole down and fix the expansion bolt.

After installing the special mounting devices for the concrete beam, people can continue with the next fan installation steps.

They are confirming the position of the wire rope. The four-wire ropes should be in the same front, back, right, and left positions. The clamping Angle with the horizontal plane should be greater than or equal to 45° (if the Angle with the horizontal plane is less than 45°, the fan blade should be installed to swing as a whole). The four-wire ropes should be tightened.

Electrical wiring. The order of the three wires is yellow, blue, and red; the wiring must be separated, can not be strung, screw to tighten, and the ground must be connected.

We are adjusting the level. The intersection level of play must cross intersection review, check whether the extension rod and motor vertical in the same line, four-wire rope above eight wire rope clips must be caught in the same place, one is for the sake of aesthetics, two it is to reflect our detail, wire rope clips must tighten, slide fastener, if any, must be in new steel wire rope clip.

I am installing fan blades, security reinforcement plates, and undercover.

Winding displacement. A threading pipe above two tiger cards, installed about 1 meter at the location, the tiger card must be on the buckle, galvanized pipe to the electrical box outlet.

Fixing electricity box, and connecting pipe joint. Galvanized pipe and corrugated hose connection must be covered with insulation tape; motor lines do not leave too long to be beautiful.

After all the above steps, one set of HVLS ceiling fans would be installed well in a concrete structure workshop.

When industrial HVLS ceiling fans are installed in concrete structure workshops, they can help the air to circulate better. The airflow is conical from top to bottom and pushes toward the ground, flows in a horizontal direction to the ground, and encounters side barriers or proximity. After the horizontal airflow of the fan is pushed up to the roof, it can achieve effective all-around overall ventilation and effective cooling of personnel in tall spaces. It can also effectively cool down unenclosed spaces with low environmental requirements.

Due to this advantage, workers working in concrete building structure workshops could gain a comfortable working environment. Leaders of workshops could save a lot of costs. One side is that workers can improve working efficiency, and the company then can make more profit from products. The other side is that when using HVLS ceiling fans, other ventilation systems, such as air conditioners and air coolers, can reduce the used quantity or even not need to turn them on. After installing HVLS ceiling fans, the concrete workshops don't need to purchase small ceiling fans, as one set of our large HVLS ceiling fans can replace many small ceiling fans. This greatly improves the aesthetics of the factory environment.

Source: Gaxiaofan Press Department

Publication Date: 9/10/2021